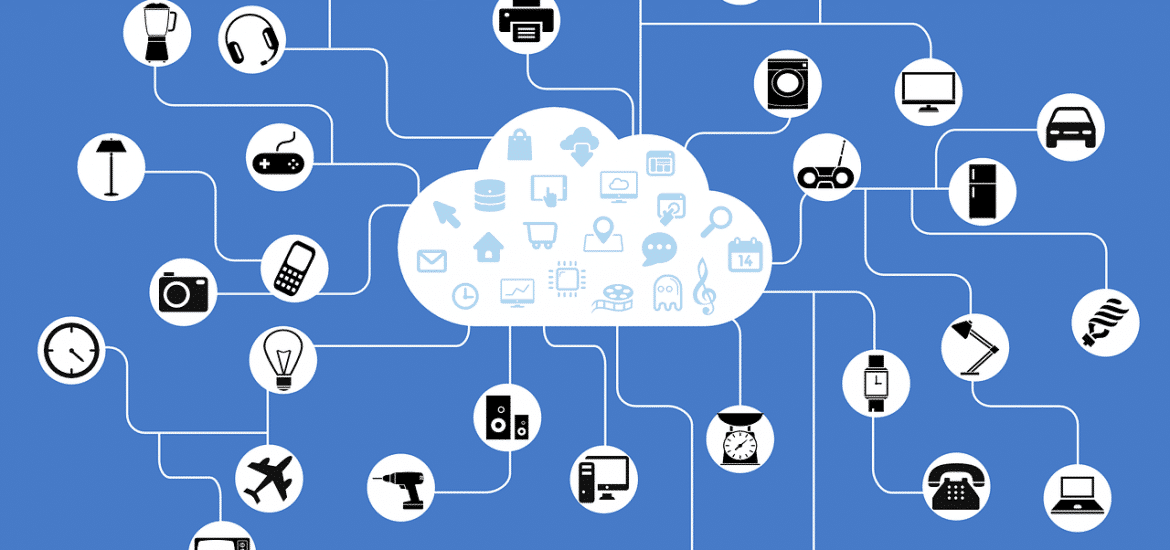

The workplace of tomorrow will be a smart workplace where everything communicates with everything else. This is essentially the definition of the Internet of Things or IoT. Smart devices are all around us and their ability to talk to each other is only getting better.

On a different front, you have the IIoT (Industrial Internet of Things), where industrial machines and embedded systems talk to each other to create smart factories. The IIoT is transforming the face of manufacturing although in an incremental way as compared to the consumer IoT.

In manufacturing, there already exist embedded systems that communicate with each other. This are known as Machine to Machine (M2M) systems. The real upgrade is being driven by the integration of big data, machine learning, and analytics into these existing communications.

Some of the results of this are as follows:

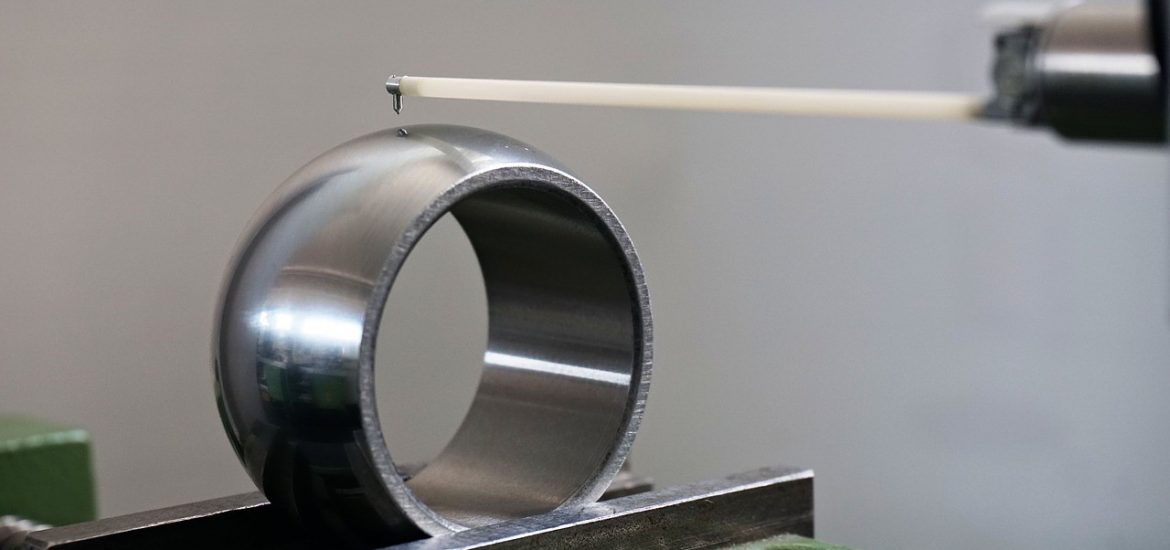

1. Better Quality Control

The Industrial Internet, the foundation of the IIoT, will offer enhanced connectivity to various systems across plants enabling line managers to identify issues before they affect overall operations.

What this will do is create a scenario where instead of the managers telling the machines what to do, the machines will be responsible for offering optimized options to better improve the overall quality of results obtained.

For example, in a vehicle manufacturing plant, IIoT components will be able to identify an issue with a certain part of a batch of cars being manufactured. This would help the plant manager catch the issue in time and avoid a recall.

2. Greener Practices

One of the major challenges industries face is pollution. Frequently, the byproducts of their activities prove to be toxic to the environment. The IIoT can go a long way in solving this. One way they can achieve this is through an enhanced integration of green policies within the overall framework of how they operate.

Think of it as building a conscience into the overall system. By communicating with each other and identifying areas that can be optimized for greener practices, these systems can play a greater role in making the work environment and the entire plant greener.

3. Enhanced Efficiencies

Efficiency = money saved. When a costly recall is avoided, this can save the vehicle manufacturer billions. When a potential oil spill is caught in time, this saves the oil company billions.

Zooming in, when a line manager can see what is happening at the factory at a granular level thanks to IIoT, this provides a level of flexibility currently unavailable. As efficiencies go up, costs go down, helping industrial firms to invest more in innovation, staff benefits and overall improvement of the business.

The Industrial Internet of Things differs from the more consumer-focused Internet of Things but still represents the same set of advantages. Firms that embrace this new reality will see massive cost savings and an enhanced ability to respond to shifting markets and market practices. While still in its infancy, the potential this modern technology has to transform how industries work can only be summarized as being unlimited.